How to Measure Pipe Size:

Measuring pipe size can be a little confusing at first, but anyone can learn how to do it. To find the right size, first figure out if you need to measure the outside or inside diameter, then measure it with a ruler or tape measure. Then you’ll need convert the measurement to the “nominal” pipe size, or what that pipe will be called in the store. Measuring pipe size is an important skill to have for any piping project.

Measuring the correct diameter

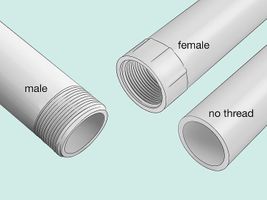

1. Determine if your pipe is male, female or has no thread:

2. Find the outside diameter if the pipe is male or has no thread:

The outside diameter is from outside edge to outside edge across the pipe. To find it, measure around the circumference of the pipe with flexible measuring tape. Divide the circumference by pi, or about 3.14159.

- For example, if the circumference is 12.57 inches (319 mm), you would divide by pi, and get an outside diameter of about 4 inches (100 mm).

- Use string to measure if you don’t have measuring tape. Mark the point on the string where it wraps around the circumference. Then remove the string, measure it against a ruler, and divide that length by pi.

3. Measure the inside diameter if the pipe has female thread:

That is the distance across the middle of the pipe, not including the thickness of the pipe walls. Use a ruler or a caliper and measure at the end of the pipe, where there is a cross section.

- Remember not to measure from the outside edges, but rather from inside edge to inside edge.

Pipe Size Names

Nominal Pipe Size (NPS)

NPS is an abbreviation of Nominal Pipe Size, which is a term used as a guideline number defining the diameter of the pipe. Nominal pipe size refers to only the outside diameter (OD) of a pipe making it somewhat vague. For example, when we say pipe size is 2 NPS, it refers to all the pipes having 2.375-inch (or 60.3 mm) as outside diameter irrespective of wall thickness and inside diameter (ID).

Nominal Bore (NB)

NB is the European designation equivalent to NPS, in which sizes are measured in millimetres. NB (nominal bore) is also frequently used interchangeably with NPS.

Diameter Nominal (DN)

This is the international and European metric method used to describe NPS (or NB). DN pipe sizes numbers are therefore different to NPS. For example, the metric equivalent of an NPS 6 pipe (6”) is DN 150. (To convert from NPS 6 to DIN simply multiply the 6 x 25=150. (150mm).

Outside Diameter (OD)

OD is the outside diameter of the pipe and is fixed for a given size.

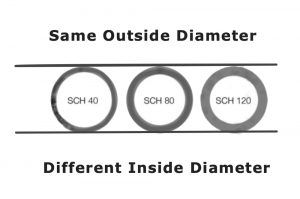

The NPS is very loosely related to the inside diameter in inches, but only for NPS 1/8 to NPS 12. For NPS 14 and larger, the NPS is equal to the outside diameter (OD) in inches. For a given NPS, the OD stays constant and the wall thickness increases with larger schedule (SCH). For a given schedule, the OD increases with increasing NPS while the wall thickness increases or stays constant.

Converting nominal pipe size

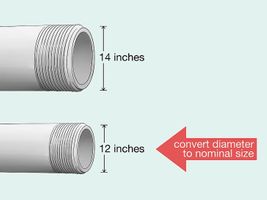

1. Convert the diameter to nomimal size if its smaller than 14" (360mm)

If its 14 inches (360 mm) or more, you don’t need to convert it, because the diameter will equal the nominal diameter already.

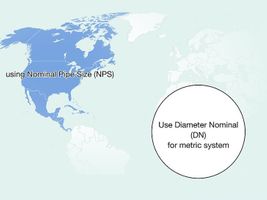

2. Do you need to convert to NPS or DN

Convert to Nominal Pipe Size (NPS) if you are in North America, or Diameter Nominal (DN) if you are using the metric system.

- If you are unsure, it could help to go to the website of a store in your country that sells pipe. If they mark pipe with inches, then you need the NPS system.

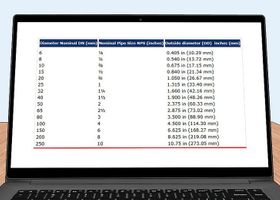

3. Convert measurement of internal or outside diameter to nominal size

Nominal size is what the pipe will be called in the store. You can do this using a table.

- This table is helpful for NPS measurements:

- This table has both NPS and DN measurements:

- For example, if you measured a diameter of 1.05 inches (27 mm), this would translate to a nominal size of ¾ in NPS, or 20 in DN.

Extra Tips:

-

Tables can also help you find out the “Schedule” of your pipe, which is related to the wall thickness.

-

If you have tubing, instead of piping, you don’t need to convert to nominal diameter. Tubing is named based on the outside diameter.

What are Pipe Schedules?

Steel pipe schedules are a way to describe the wall thickness of the pipe. This is a critical parameter as it is directly related to the strength of the pipe and the suitability for specific applications. A pipe schedule is a dimensionless number and is calculated based on the design formula for wall thickness, given the design pressure and allowable stress.

The most common schedule numbers are 40 and 80. As the schedule number increases, the wall thickness of the pipe increases. The schedule number is roughly calculated as per formula below:

Schedule = 1000 x (P/S)

P = Internal service pressure of pipe (psig)

S = Ultimate tensile strength of the pipe material (psi)

The different types of Stainless Steels

In addition to chromium, nickel, molybdenum, titanium and niobium, other elements may also be added to stainless steels in varying quantities to produce a range of stainless steel grades, each with different properties. Stainless steels are mainly used when corrosion or oxidation is an issue, as the function that they perform can’t be duplicated by other materials for their cost. Over 100 years ago, it was discovered that a minimum of 12% chromium would impart corrosion and oxidation resistance to steel; hence the name “stainless steel”. Several different types of grades of stainless steel have been developed. Below are the different stainless steel grades explained in more detail.

All stainless steels can be divided into five basic categories:

- Austenitic

- Ferritic

- Duplex

- Martensitic

- Precipitation hardening

Austenitic and ferritic grades account for approximately 95% of stainless steel applications.

Austenitic:

Austenitic stainless steels contain chromium in the range of 16 to 30% and a moderate to high percentage of nickel. These grades cannot be heat treated to increase hardness. Most stainless steels falling under this category are non-magnetic because they contain high amounts of austenite. Even though some of the metals like grade 304 and 316 have iron in their chemical composition, they are austenite, meaning they are not magnetic.

Ferritic:

These are plain chromium stainless steels with varying chromium content between 12 and 18%, but with low carbon content. Ferritic stainless steel owes its magnetism to two factors: its high concentration of iron and its fundamental structure. Ferritic steels are high-chromium, magnetic stainless steels that have a low carbon content. These steels are magnetic but can’t be hardened or strengthened by heat treatment. The can be cold worked and softened by annealing. As a group, they are more corrosive and crack resistant than the martensitic grades, but generally inferior to the austenitic grades. These are straight chromium steels with no nickel, like the martensitic grades. They are used for decorative trim, sinks and automotive applications.

Duplex:

These are stainless steels containing relatively high chromium (between 18 and 28%) and moderate amounts of nickel (between 4.5 and 8%). The nickel content is insufficient to generate a fully austenitic structure and the resulting combination of ferritic and austenitic structures is called duplex. Most duplex steels contain molybdenum in a range of 2.5 - 4%. They are used in Chemical processing, transport and storage. Pipes for production and transportation of oil and gas. Oil and gas exploration and offshore rigs and refining. Duplex grades are the newest of the stainless steels. This material is a combination of austenitic and ferritic material. This material has higher strength and superior resistance to stress corrosion cracking.

Martensitic:

Martensitic stainless steels were the first stainless steels commercially developed (as cutlery) and have relatively high carbon content (0.1 - 1.2%) compared to other stainless steels. They are plain chromium steels containing between 12 and 18% chromium. Martensitic stainless steels, widely used for both table knives and trade knives, contain from 12 to 18 percent chromium, imparting corrosion resistance, and from 0.12 to 1 percent carbon, permitting a great degree of hardening by heat treatment. Because the cooling rate is so sudden, carbon does not have enough time for diffusion. Therefore, the martensite phase consists of a metastable iron phase oversaturated in carbon. Martensitic grades were developed in order to provide a group of stainless alloys that would be corrosion resistant and hardened by heat treatment. The martensitic grades (also known as the 400 series) are straight chromium steels containing no nickel and are also magnetic. The martensitic grades are mainly used where hardness, strength and wear resistance are required.

Precipitaion Hardening:

Precipitation hardening stainless steels have been formulated so that they can be supplied in a solution treated condition, (in which they are machineable) and can be hardened, after fabrication, in a single low temperature "ageing" process. The precipitation hardening (PH) stainless steels are a family of corrosion resistant alloys some of which can be heat treated to provide tensile strengths of 850MPa to 1700MPa and yield strengths of 520MPA to over 1500MPa - some three or four times that of an austenitic stainless steel such as type 304 or type 316. Due to the high strength of precipitation hardening stainless steels, most applications are in aerospace and other high-technology industries. Applications include: Gears. Valves and other engine components.

Precipitation hardening grades offer the designer a unique combination of fabric ability, strength, ease of heat treatment, and corrosion resistance not found in any other class of material. While designed primarily as a material to be used for bar, rods, wire, and forgings, martensitic precipitation hardenable alloys are beginning to find more use in the flat rolled form. Developed primarily as aerospace materials, many of these stee