Pipe Fittings are defined as the pipe components that help in pipe routing for directional changes, size changes, and branch connections. Elbows (90 and 45 Degrees), Reducers (Various sizes), Tees, Connectors, Caps, etc are pipe fittings and widely used in both the pipe and plumbing industries.

In terms of steel pipe fittings that you would be able to use for your pipeline projects, you will find two of them to be quite popular: Socket weld fittings and Butt weld fittings. Since both of them seem to have their own share of pros and cons, you might be confused about which one is best for your particular purpose. Because of this reason that we have taken the responsibility of drawing up a comparison between them. Socket welding can be used for pipes with small diameters, and it is generally applied to pipes or pipe fittings whose diameters are less than DN50. Butt welding is widely used for pipes with big and small diameters, and threaded welding or socket welding is used for pipes with small diameters (See below).

Types of Fittings

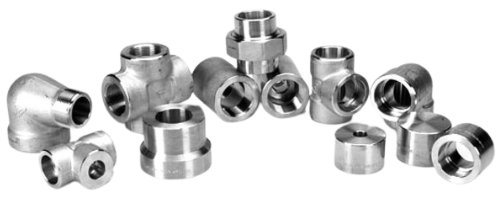

Socket-Weld Fittings

A Socket Weld is a pipe attachment detail in which a pipe is inserted into a recessed area of a Valve, fitting or flange. In contrast to buttweld fittings, Socket Weld fittings are mainly used for small pipe diameters (Small Bore Piping); generally for piping whose nominal diameter is NPS 2 or smaller. A socket weld refers to the weld that joins specific pipe fittings like reducers, tees, and elbows with pipes. The pipe is permanently joined to the recessed region of the joint with a socket weld. The pipe fittings connected by this method are called socket weld pipe fittings.

Buttweld Fittings

Buttwelds are weldable pipe fittings used in changing the direction, branching, reducing, or enlarging pipe size in a piping system. Using buttweld fittings utilizes minimal space compared to other types of fittings and guarantees permanent leakproof connections. A buttweld fitting is a weldable pipe fitting that allows for change of direction of flow, to branch off, reduce pipe size or attach auxiliary equipment. Forged Steel buttweld fittings are manufactured in accordance with ANSI / ASME B16.

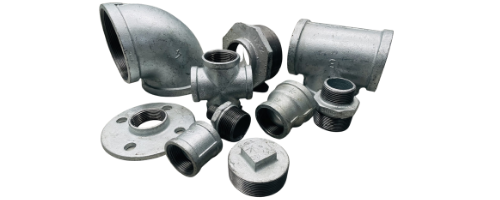

Gal Mal Fittings

Galvanized fittings are made from malleable iron, a type of mild steel with excellent strength and corrosion resistance. It is zinc-coated, which prevents rusting. Our galvanized malleable fittings are designed to work well with air, steam, and water. When you are putting together a water line, you want fittings that will not rust or corrode.

Black Iron Fittings

The black steel finish of these fittings is created in a process during manufacturing of this pipe fitting after casting. Its name comes from the scaly, dark-colored iron oxide coating on its surface. It’s used in applications that don’t require galvanized steel. This pipe is not used for drinking water but black steel pipe’s strength makes it ideal for transporting water and gas in rural and urban areas and for conduits that protect electrical wiring and for delivering high pressure steam and air. The oil and petroleum industries use black steel pipe for moving large quantities of oil through remote areas.

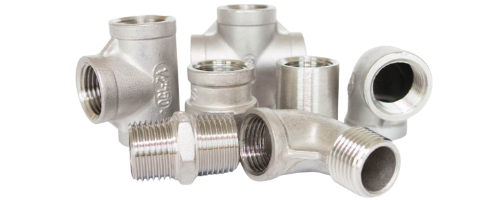

Stainless Steel Fittings

All stainless steels have a high resistance to corrosion. This resistance to attack is due to the naturally occurring chromium-rich oxide film formed on the surface of the steel. Although extremely thin, this invisible, inert film is tightly adherent to the metal and extremely protective in a wide range of corrosive media. The film is rapidly self repairing in the presence of oxygen, and damage by abrasion, cutting or machining is quickly repaired. Stainless steel tube fittings are all the connecting fittings that butt weld to tube. These fittings are measured on the outside diameter of the tube and are available in grades 304 or 316 stainless.

Mild Steel Fittings

Mild steel is quite malleable, even when cold. Hence, along with having high tensile strength and impact strength properties, it can be easily formed into Mild Steel Fittings. When cold, carbon steel grades that have a higher content of carbon usually shatter or crack under stress. In order to improve its corrosion resistance properties or to make it long-lasting and rustproof, Mild Steel Pipe Fittings are often galvanised or coated with the right paint. In addition to the aforementioned properties, what makes Mild Steel Weld Fittings more attractive to many buyers is the fact that this alloy is relatively cheaper than most steels grades.

High Pressure Fittings

High-pressure fittings are high-performance fittings used in connecting, changing the direction, branching, reducing, or enlarging the pipe size in severe environments. They are specially engineered to withstand extreme pressure and temperatures of demanding applications such as water jet cutting, high-pressure pasteurization, hydraulic power units, and much more.

Galvanised Fittings

Galvanized steel pipe is covered with a zinc material to make the steel pipe more resistant to corrosion. The primary use of galvanized pipe is to supply water to homes and buildings. The zinc also prevents the buildup of mineral deposits that can clog the waterline.